Specification:

¡ô Gluing width: 500mm

¡ô Adjustable speed

¡ô Power supply: 220V/2000W

¡ô Dimensions: 800¡Á510¡Á270mm

¡ô Weight: 66.0kgs

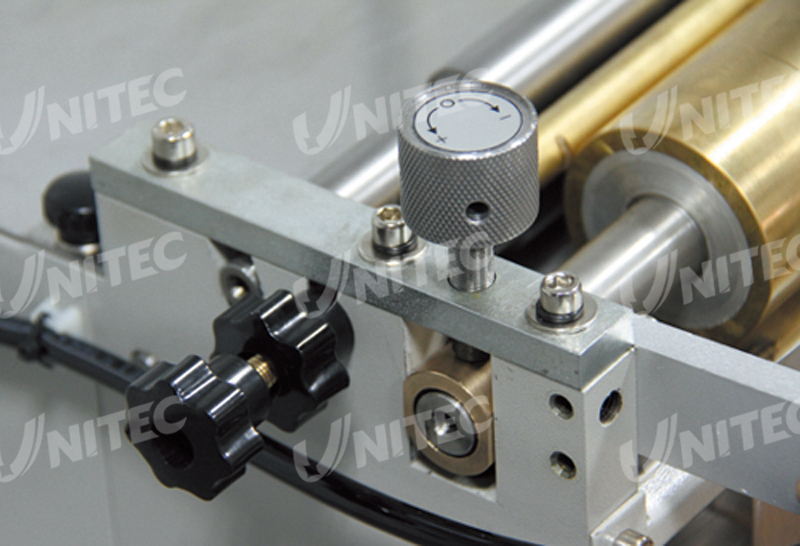

Copper alloy made Glue application roller and Glue tray.

Independent homothermal impermeable heater unit.

Auto water replenishing, water quantity can be controlled.

Stepless glue application speed.

Microthermal animal glue drying quickly, no deformation and lower cost.

Animal glue and water-based white latex are both available.

¡ô Animal glue, jelly glue and water-based white latex can be used independently.

¡ô Glue application roller and glue tray adopt copper alloy which makes heatconduction

and glue application well-distributed, fast heat up.

¡ô Add appropriat e water by Automatic water replenishing device according to the glue

condition in order to avoid glue becomes dry and hard.

¡ô Independent homothermal impermeable heater unit ensure the fast heating up and

accurate temperature control. Lower the cost by using Jelly glue and Animal glue.

¡ô Stepless glue application speed, running smoothly and suitable for various thickness

paper.

¡ô No distortion, no mildew, no bubble and no cracking, environmental protection.

¡ô The thickness of the glue can be adjusted according to the job needs.

Copper alloy made Glue application rolle Automatic water replenishing

Adjustable glue quantity Peel the glued paper automatically

The advantages and features of Animal Glue:

Forms a strong and long-lasting bond, suitable for various of materials.

Dozens of different animal glue with open times ranging from 2 seconds to three minutes for different job needs.

Non-hazardous, non-toxic, biodegradable.

Microthermal impermeable heating up.

Soluble in water, excellent initial wet tack.

Cycle use, lower the cost of production.

Animal glue is protein colloid glue which formed through hydrolysis, extraction and drying of the collagen from animal skins, bones, tendons, and other tissues.

Animal glue has excellent stickiness and tightness on most materials, terrific alternate hot and cold resistance, and appropriate open time.

There is no corrosiveness and harm to the machine and operator.

Usage: Put the Anmal glue in the glue tray and melt it first, then adjust the temperature to

40-70¡æ till the glue completely melted and running the machine. Put 10-20%

water before the melting to adjust the consistence of the gule as need.